Power

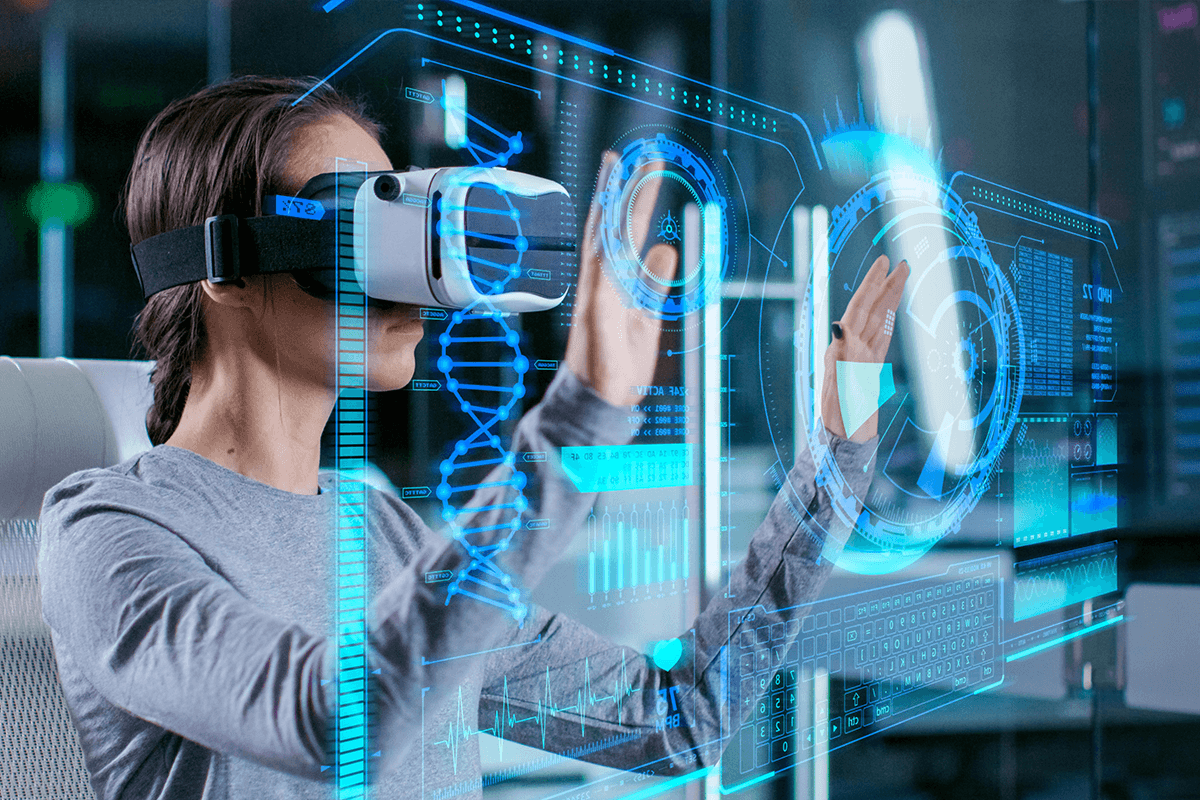

Our mission is to help companies successfully implement

VR & AR hardware solutions.

Fueling the power industry with Digital Reality

The fundamental nature of the power and utility sector requires physical and hands-on labor. As a result, technology adoption and maintenance in the industry can be very costly as well as tenacious. However, the multifunctional nature of Digital reality makes the investments worthwhile as they simplify and reform the work processes. Augmented, Virtual and Mixed Reality fit well in the power industry because they provide ample opportunities to increase efficiency, improve safety, and provide on-ground training. And as the power industry increasingly utilizes the benefits of Simulation technologies, it can improve operation efficiency manifolds, and also serve customers better.

The rise of digitization in Power

A recent report estimates that the AR and VR market share in the power sector will reach $18 billion by 2022. Moreover, the industry constituted 17% of the worldwide share of AR hardware shipment in the year 2018. Additionally, the power segment is expected to register a 15-20% rise in efficiency due to the applications augmented and virtual reality. Simulation technologies have the potential to bring down the plant and output downtime by as much as 30%, reduce the frequency of accidents and injuries by 43% and reduce the time for adoption of new equipment by 27%. The technology also holds the capacity to enhance the worker and equipment safety, provide hands-on training, and access remote parts and functions in an immersed environment.

Uses of AR and VR for Power utilities

With the rapid increase in adoption rate, it is clear that AR, VR and MR technologies are bringing new ways of enhancing manufacturing capabilities throughout the product lifecycle. The industry is benefiting from the implementation of digital reality in more than one way. Augmented Reality has created a platform for real time instructions for assembly and configuration, overlaying design components onto existing modules, digital viewing of the equipment design as well as visualizing specific components and functions beyond physical barriers. On the other hand, virtual reality assists in creation of product twins to simulate the real-world environment, remote collaborations across locations, simulating human motion for a process to engineer alternative actions and virtual walk throughs & immersive inspection of plants. Virtual reality also offers a more immersive way of imparting on the job and safety training to the workers. These practical applications help the teams by saving time through better planning, reducing errors & complexity through accurate testing and increasing efficiency, safety and productivity.

The way forward for the Power sector with XRTECHLINE

Digital reality has revolutionized the functioning of the power sector and will continue to add value in terms of knowledge and productivity. With more and more industry players turning to simulation to gain a competitive edge, our specialized teams at XRTECHLINE allow you to leverage the technology to its best. We fully understand the scope and depth of the potential that Simulation technology holds, and through our unparalleled services & ideas, enable you to stay ahead of the competition.